Recently the transport market has been flooded with a number of technological innovations regarding intermodal transport, which is one of the most optimal options in terms of the macroeconomic scale of an enterprise. However, when making a decision whether to send a unit load in this way, we must be aware of the opportunities and risks arising from the intermodal option.

Indisputable advantages of this type of transport include, for example, the reduced transport costs (the further the distance for the goods to travel, the greater the economy), lack of exposure to communication problems (such as traffic jams, no thoroughfare, etc.) and others, resulting from the fact that a large batch of cargo can be sent at the same time.

Unfortunately, nothing is perfect, especially in transport, and this solution has its disadvantages too. The drawbacks undoubtedly include the need to use specialized handling equipment. The ecological “intermodal” is also unable to compete with road transport on shorter routes in terms of the transit time. So when the customer clearly cares about time, we might just not make it in time or not fit into the time schedule. Those who have ever dealt with combined transport know what I mean.

Of course, there are exceptions to this rule. By having one’s own block train, we can influence its time schedule, however, this is a very rare situation. The limitations may also concern the lack of a well-developed structure or appropriate connections, and it sometimes happens that such transport is simply not profitable over short distances. It is worth noting that when calculating the rates for intermodal transport, what must be taken into account are all the components of the transport, including the costs of road transport (trucking) and storage (in the necessity of bulking cargo required for the economic viability of rail transport), as well as transshipment costs. Naturally, wherever the precise logistics of ‘just-in-time’ or ‘just-in-sequence’ are needed (e.g. general cargo, automotive or the printing and publishing industry), “intermodal” transport cannot compete with road transport.

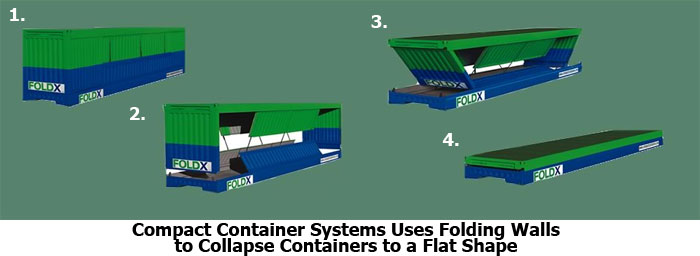

I still believe that it is always worthwhile to keep track of potential new logistics and transport solutions which, if not now, then in the future will help to optimize costs and become more competitive. For a few years now it has been said thatthe storage of empty containers is just as expensive as bringing them back. At the end of the day, the empty containers must be transported back to the base from where they were collected, and it is the carrier’s customer who bears the cost. When presenting the offer, this must be made clear. Of course the biggest players have optimized this problem to some degree by building a large transport network which provides cargo for the return of the container, but it is not always that simple.

Source: scdigest.com

And here comes the new technology of future containers. New designs of containers will allow them to be arranged in 10 to 12 layers during maritime transport. Each of them must be able to withstand a pressure of 350 tons, and that is impressive! Before they can be legally sold and used, they must obviously obtain the necessary approvals and certificates awarded by the relevant institutions and regulatory bodies of the maritime sector. From what I know, and I am passionate about intermodal transport, some companies are already close to this solution. At present, there are containers available on the market which can be stacked in 4 layers and placed on a train carriage. For now, that is a big step forward in reducing the costs of the return journey of containers in European traffic. Can they already be considered the containers of the future?

Author:Mateusz Burczyk – Export LTL & FTL Lider